Single end extrusion coating line

YarnStar 3+ - Coating - Cooling - Winding+Automation

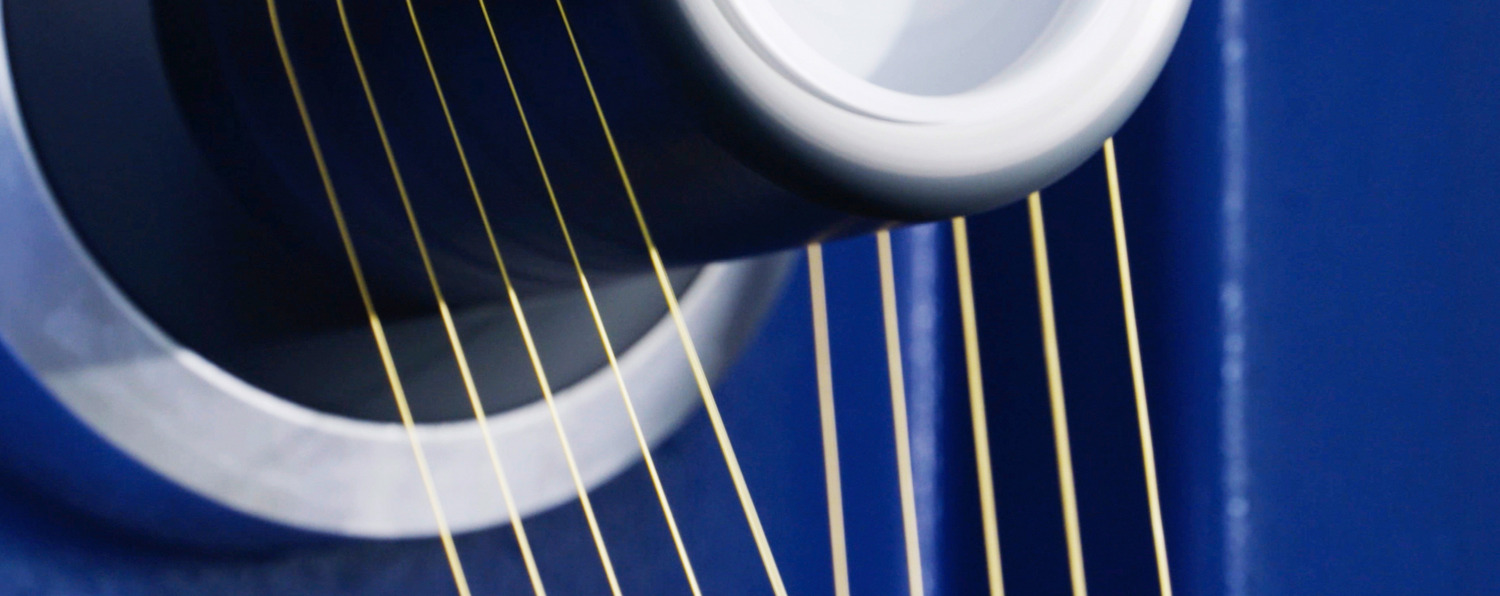

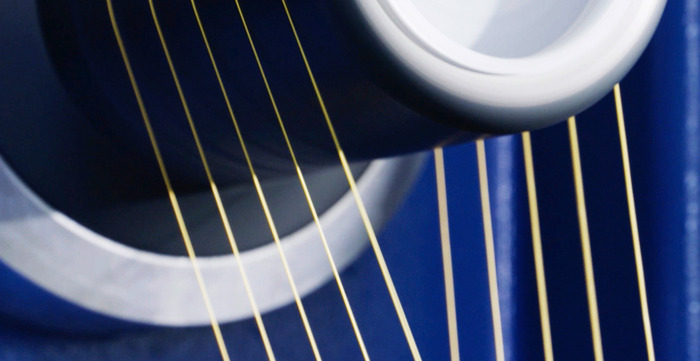

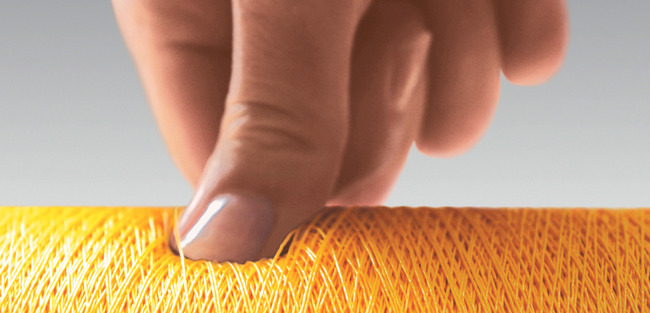

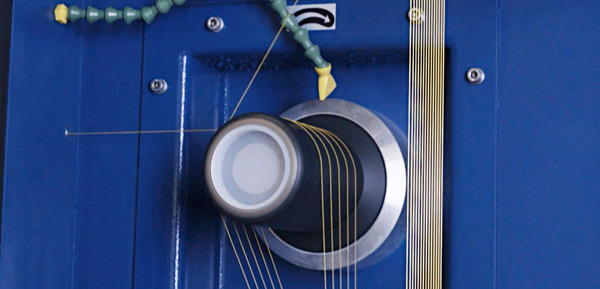

The YarnStar 3+ is a mono and bicolor single end extrusion coating line designed for a high degree of flexibility and a broad application range.

The extremely compact line coats single ends of textile and technical yarns in excellent coated yarn quality. The integrated line concept of the YarnStar 3+ achieves production speeds up to 1,500 m/min.

Fewer cross marks due to soft winding

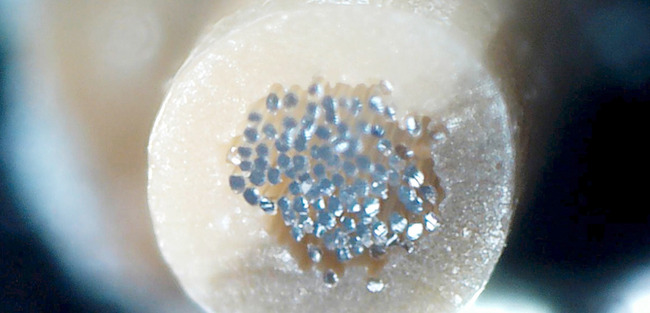

Exact core yarn centricity

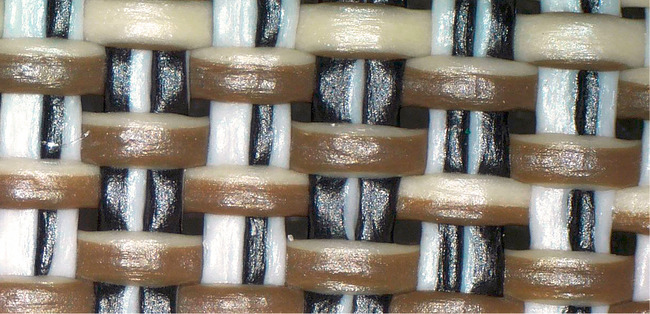

Bicolor fabric

Unwinding creel for polyester feed packages

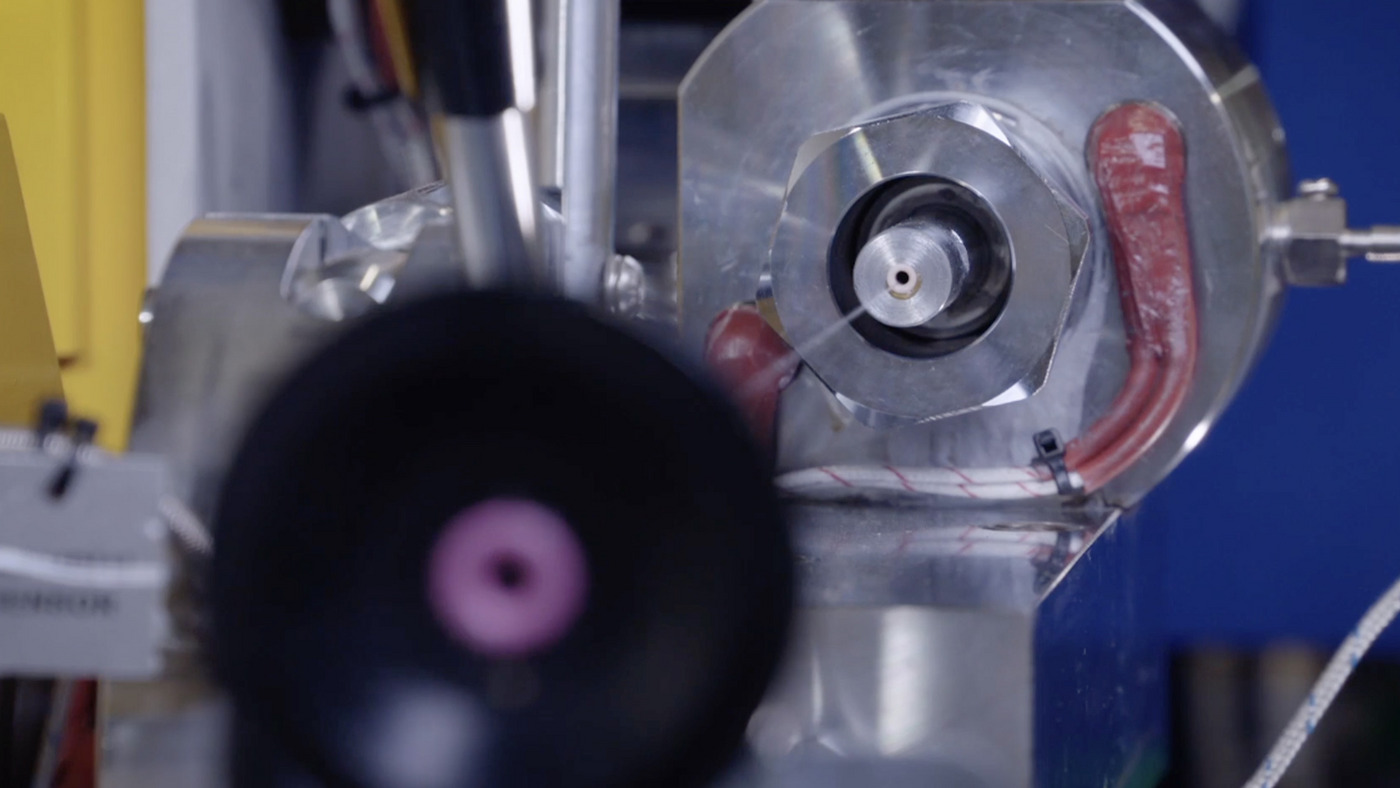

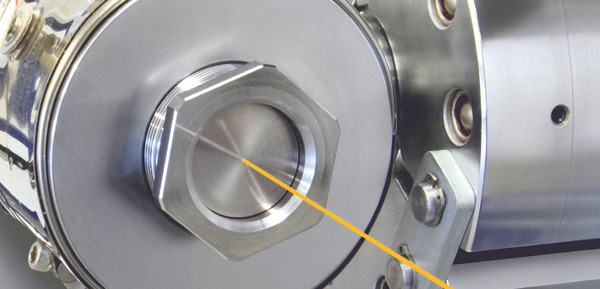

Screw extruder with 5 heating zones

Chill unit

Automatic precision winding and bobbin change

The finished package is transported to a storage unit which is emptied from time to time by the operator.

Your advantages